Feudalist China experienced its peak at the Tang Dynasty with it capital in Changan (today’s Xian) and the second capital at Luoyang, and at both places a great amount of tri-color porcelain were excavated.

In the Tang Dynasty copper utensil was forbidden because the limited resources of copper had to be used for mint to support the developed foreign trade; tea drinking became very common and porcelain tea sets were needed in great numbers; special government department was set up to oversee the production of porcelain, lacquer, metal and dyeing and weaving. All these factors, in particular foreign trade through the Silk Road, promoted the prospering of porcelain production in the Tang. A large amount of porcelain were sold to foreign countries, and at the same time, forms and patterns of porcelain absorbed some foreign influence, especially the culture of western Asia.

Section I A Landscape with the south producing celadon and the north white porcelain

Xing Kiln in the north was known for its production of white porcelain and Yue Kiln in the south was known for its production of celadon. This is the so-called landscape of celadon in the south and white porcelain in the north in China’s history of porcelain. Porcelain wares of Tang excavated from the south were mostly celadon, and those excavated from over 10 kilns in the north were mostly white porcelain. But, celadon was still the main product in the whole country.

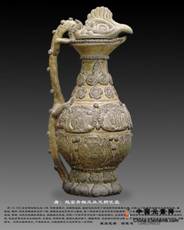

A pot with a phoenix head and a handle shaped like a dragon Yue Kiln of Tang

1.Celadon of Yue Kiln: As tea-drinking became more and more popular and the demand of celadon by the imperial government increased, the quality of Yue Kiln products, which marked the highest level in celadon of the time, were improved by a big margin and owned its special style as its glaze was green and even, its contours elegant and beautiful and its ornamental patterns were simple and plain. The inner body of late Tang celadon not only had a smooth, lustrous surface, but also was of exquisite and compact quality, and the glaze was all over the body and thinner.

2.

A sample of Tang White Porcelain

White porcelain produced by Xing Kiln: Xing Kiln (in Neiqiu County of Xingtai, Hebei) was very big and the production was huge. Its inner body was robust, exquisite and white. The glaze was snowy and in silver. It also had rich varieties. It laid a solid foundation for later colored ornament.

Section II Development of Porcelain in Other Glazes

1. Yellow porcelain of Shouzhou: The kiln was in today’s Huainan city of Anhui. Its inner body

was thick and the glaze was yellow as shown in the picture on the right.

2. Black porcelain: the inner body was thick and heavy and of a flat bottom.

3. Tang porcelain with dappled glaze: mainly produced at Lushan Kiln of Henan Province.The glaze was

applied twice, each time with a different oxide of a different metal and burnt twice. The picture on the left is a

sample.

4. Porcelain of colored glaze: colored glaze began to appear since Mid-Tang at Changsha Kiln. Its patterns were in rich varieties ranging from figurines, birds, flowers, to animals, mountains and waters.

5. Porcelain made of mixed clay: There were two ways to mix the clays: one was to cover the entire body in white and gray or in brown and white, which would look like a feather or wood veins; the other was to cover only the ornamental part. They were in the forms of cups, bowls, small plates and rectangle pillows.

Section III Advancement of Porcelain Technique

1. Improvement of Kilns: During this period, kilns in the north were somewhat improved. The kilns were composed of the fire box, the chamber, the smoke vent and the chimney, at this time, half-way down draft occurred, the draft was adjusted by the smoke vent. The replacement of cold chamber bottom by hot ones was the most remarkable improvement, and the temperature inside the chamber was even. Chambers in the south became longer at this time.

2. Change of forms: The thickness and weight of the inner clay bodies became lighter, a new wine vessel—“ying” appeared, it has a round body and a small opening.

3. New ways of patterns: the opening of pots became shorter and opening of bowls were of 4 or 5 flower petals. Tri-color and multi-colors began to be used; so was stamping of prints, designs of polo playing, figurines, lions and grapes were found on green glaze porcelain excavated from both Shanxi and Changsha, and influence from central Asia could be detested from some of them.

Section IV Blue and White of Tang

There had always been different opinions on the origin of blue and white, some held that it came into being at Jingdezhen in the Yuan Dynasty, some held that it first appeared in the Song Dynasty, others held that it was first produced in the Tang Dynasty. Archaeologists found in 1957 some fragment of a porcelain pillow at Yangzhou, and in 1983 other fragment of blue and white were found in the same place, they turned out to be Tang Dynasty blue and white. As far back as the Three-Kingdoms period, the craftsmen already knew how to use underglaze and the application of cobalt material, which are the two prerequisites for producing blue and white. Tests of the fragment mentioned above show that they were burnt at a degree between 1200℃ and 1300℃, and the colorant they used was low manganese cobalt, and they proofed to be under glaze by microscope observation and electronic probing. Experts believed that blue and white was a discovery on the basis of brown coloring and tri-color, and that cobaltous oxide was applied together with transparent glaze onto the clay body and made by one burning. The color was fresh, lively; blue over white base seems solemn and graceful in a strong orient style, and on top of that the color would never fade under the glaze.